Pvc Electrical Cable Trunking Extrusion Line

Awọn ọja Apejuwe

Pvc Electrical Cable Trunking Extrusion Line

Ogidi nkan:

PVC lulú

Gbogbo laini iṣelọpọ pẹlu:

ṣiṣu powder dabaru agberu → SJZ 55/110tabi SJSZ65/132conical ibeji dabaru extruder →ProfailiMimu → tabili Calibrator → Gbigbe ẹrọ → Ẹrọ gige →6 mita stacker

Lo: Fun iṣelọpọ ti profaili PVC rirọ, profaili PVC kosemi, Profaili àjọ-extrusion asọ-lile, extrusion profaili foomu, àjọ-extrusion Layer pupọ ati bẹbẹ lọ.

Imọ paramita

ni pato

* Gbogbo ipari laini nipa awọn mita 18

* Agbara gidi ti o jẹ nipa 30 kw

* Agbara extrusion jẹ 120-150 kg / h

* Iyara extrusion jẹ 2-3 m / min, o tun da lori iwọn trunking, iriri ẹlẹrọ ati didara mimu extrusion

Awọn ẹya akọkọ:

1. Extruder: Ẹrọ ti wa ni ipese pẹlu ẹrọ ifunni ti o pọju, eyi ti o le ṣe ibamu pẹlu iye extrusion ati iye ohun elo, ati rii daju pe awọn ọja ti o ni iduroṣinṣin ti awọn ọja.

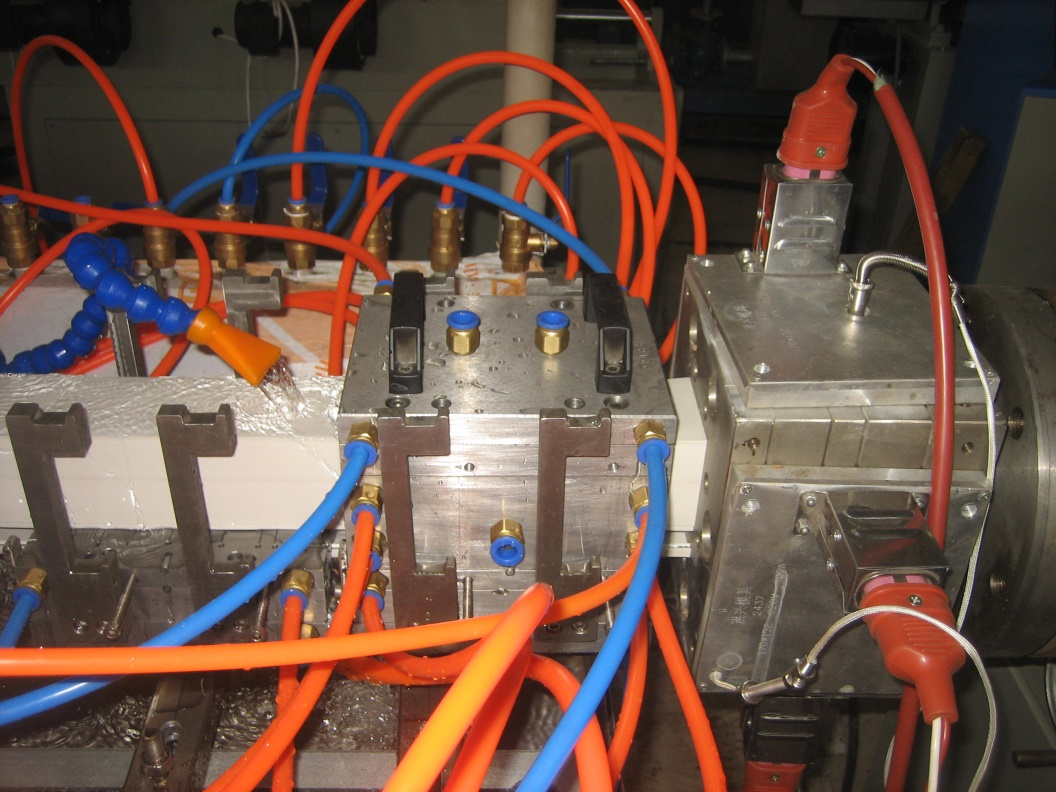

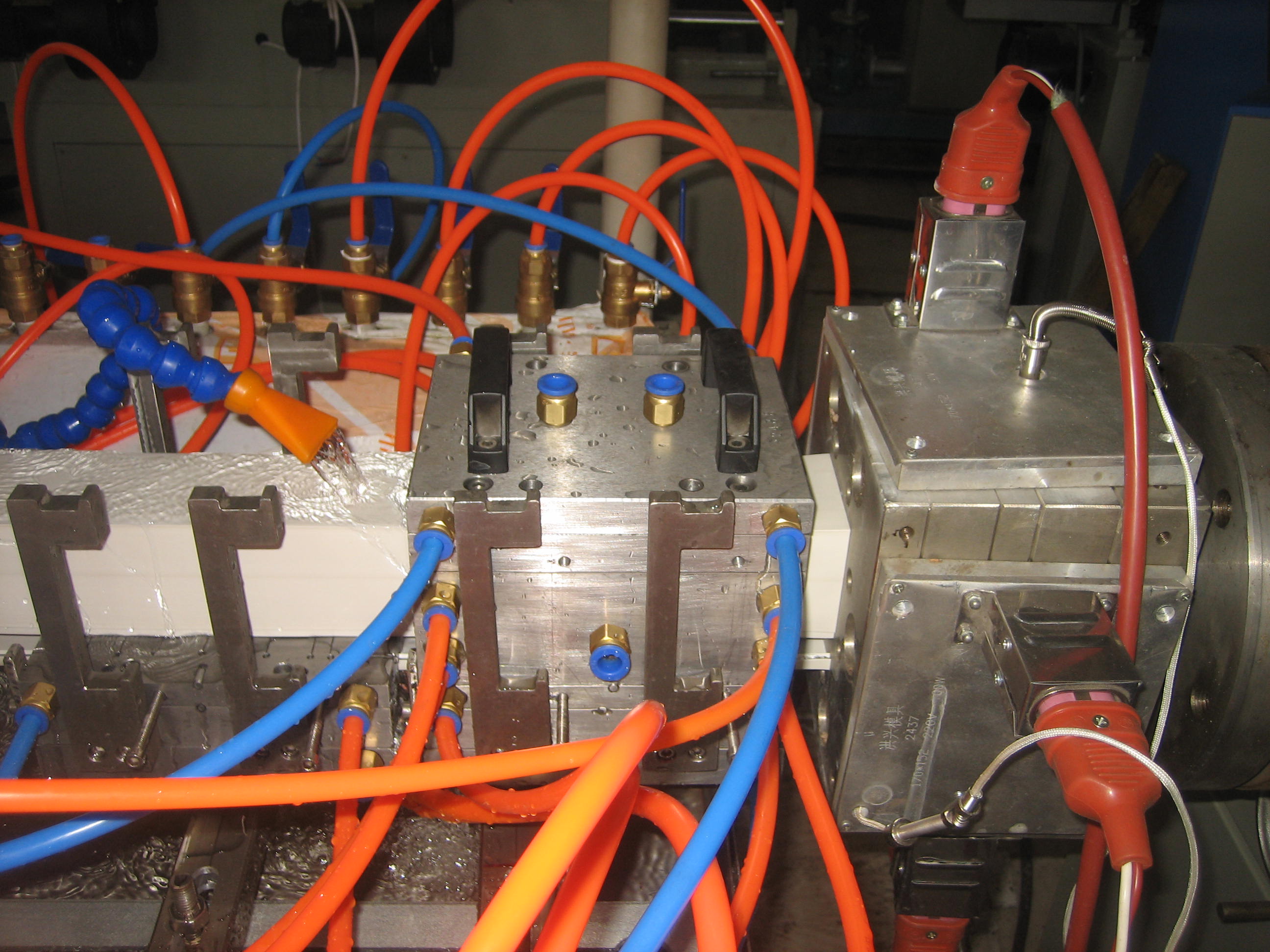

2. Mold Die: Lẹhin ti o ni iṣiro, yo, dapọ, awọn ohun elo PVC le jẹ nipasẹ skru ti a fi sinu ku, extrusion kú ori jẹ apakan pataki ti profaili ti o ṣẹda.

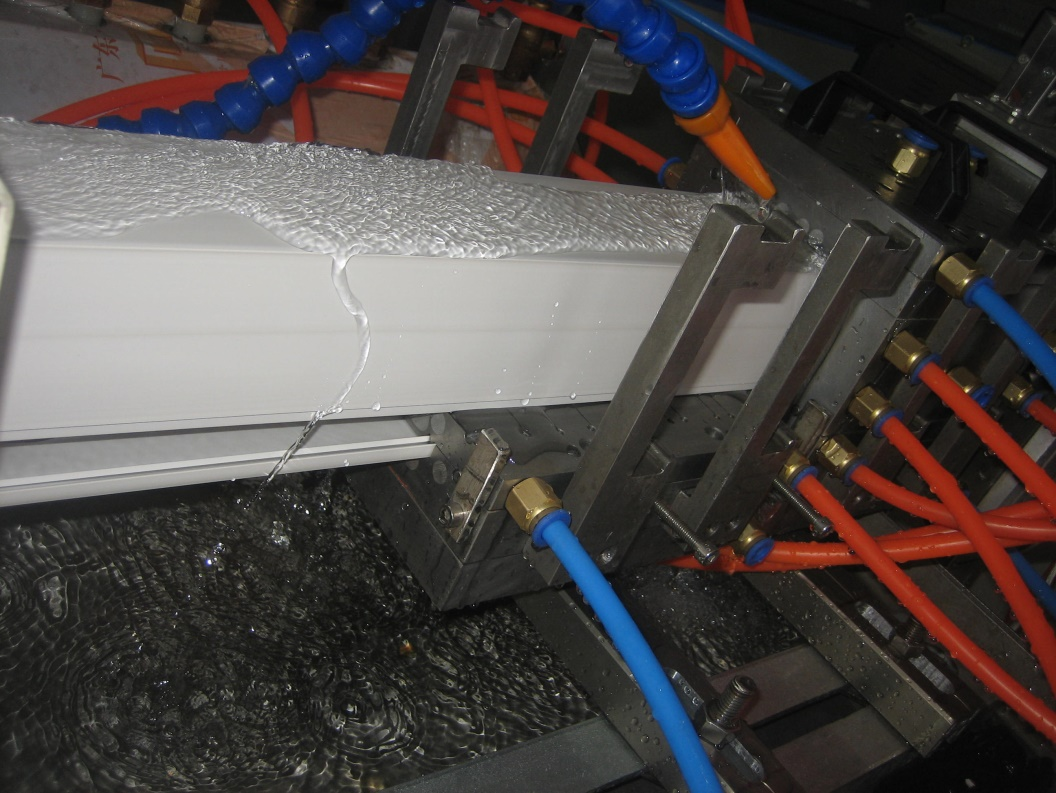

3. Vacuum Calibrating Cooling Tank ti wa ni lilo fun iwọn ati itutu agbaiye, eyiti o ni ipese pẹlu eto igbale ati eto iṣan omi, irin alagbara irin casing, ṣiṣan omi immersion immersion.

4. Ti a lo ẹrọ ifasilẹ fun aifọwọyi aifọwọyi ti o tutu awọn profaili ti o tutu lati imu ati iṣakoso igbohunsafẹfẹ.

5. Cutter: Yipada irin-ajo yoo ge laifọwọyi ni ibamu si ipari ti a beere.Ilana gige naa jẹ ṣiṣe nipasẹ itanna ati pneumatic.

| Iwọn profaili ti o pọju (mm) | Extruder awoṣe | Agbara apẹrẹ (kg/h) | Agbara alupupu (kw) |

| 180 | 51/105 tabi 55/110 | 80-120 / 120-150 | 18.5/22 |

| 240 | 65/132 | 175-250 | 37 |

| 300 | 65/132 | 175-250 | 37 |

| 400 | 65/132 tabi 80/156 | 175-250 / 250-350 | 37/55 |

| 600 | 65/132 tabi 80/156 | 175-250 / 250-350 | 37/55 |

| 800 | 80/156 | 280-350 | 55 |